Straddle Carriers

Straddle Carriers

Straddle Carrier 101:

General Material Handling

Straddle Carrier: Also known as Straddle Truck or Straddle Buggy

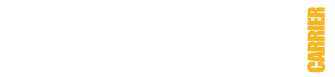

Definition 1. A self-propelled, non-road going vehicle that features a chassis positioned far above the ground. Chassis placement enables the vehicle to carry long and heavy loads beneath the chassis and between the wheels.

Definition 2. The straddle truck is typically a diesel powered four-wheel vehicle designed to straddle, pick up and transport loads of long and heavy supplies. The straddle truck is used as an efficient conveyance for intra-station movement of palletized material at many supply activities. Straddle trucks offer a faster and more efficient method of moving unitized pallet loads over intermediate distances when compared to a tractor-trailer train.

The Advantages of a Straddle Carrier Over Forklift Machinery

Gerlinger Straddle Carriers are engineered with lift shoes that range from 8 ft. to 20+ ft. long. Carriers can move long, heavy loads in a far more narrow path by hauling the load under the belly.

This innovative design provides a number of advantages when compared to a forklift hauling sideways loads.

- Stably support loads in excess of 60 ft. long under transport.

- Maneuver quickly within industrial facilities.

- Eliminate the need for counterbalance weights by straddling the loads, making the machine far lighter than traditional forklift machines.

- Centered load disperses the load weight efficiently to the machine's four wheels and decreases the ground contact pressure.

- Straddle Carriers can typically lift in excess of twice their own weight.

There are many industrial uses for choosing a straddle carrier machine, including:

- Transportation of pipe, billets, heat exchanger tube bundles, slabs, bundled or coiled materials.

- Movement of structures like bridge & tower construction, scaffolding & ladders, poles, drill casings, concrete forms, building framing and general structural materials.