Refineries

Refineries

Refinery/Petrochemical: Fast, Easy and Efficient Transport of Tube Bundles

Streamline Your Turnaround

Gerlinger Carriers excel when special handling requirements in refineries call for the flexible and efficient handling of long and large loads.

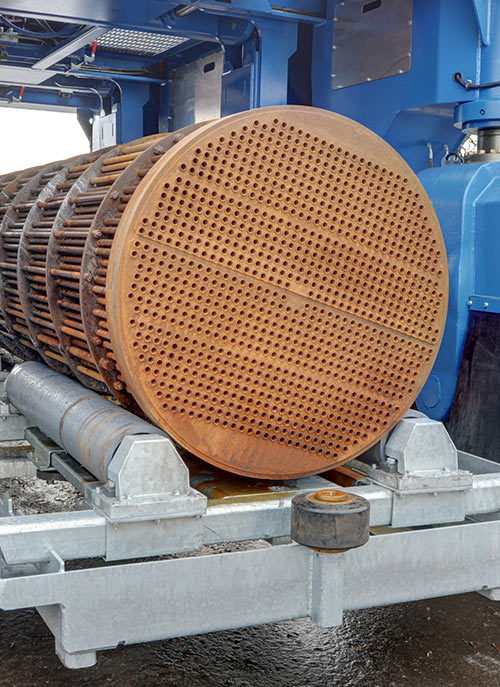

Turnaround is a time-consuming and expensive process. Downtime costs money, which makes streamlining the workflow critical to a facility's success. The petrochemical and refinery industries have long turned to Gerlinger Carrier as a solution for transporting heavy and fragile heat exchangers (tube bundles) to and from wash pads and maintenance facilities. Gerlinger Carrier is your choice for Tube Bundle carriers and rotators.

Transporting expensive tube bundles always presents a challenge when it comes to turnaround maintenance. Previously, these types of materials were transported with forklifts, semi-trucks and cranes, but that method was often complicated by the narrow turn radius in aisles and roadways, and needing cranes and rigging personnel at both ends of the project to handle the Tube Bundles again. Gerlinger Straddle Carriers with tight turn radius, lower ground contact pressure and faster transportation quickly became the go-to method for hauling tube bundles on basic load pallets under the carrier.

Straddle Carriers are also used for day-to-day transporting of items like pipe, tubing, structural steel, scaffolding, and miscellaneous components around the worksite.

Customizable, Powerful, Efficient

Proudly made in the U.S.A for over 100 years, Gerlinger is the premiere name in straddle carriers, and the industry leader in carrier design and manufacture. With lift capacities from 20,000 lbs. to 90,000 lbs., Gerlinger Carrier can help solve the toughest material handling applications to better meet your refinery transportation needs.

A powerful workhorse, some of the world's largest refineries use Gerlinger for simplified material handling chores.

Taking the Process a Step Further

Gerlinger developed a revolutionary tool that makes it quicker and easier to handle bulky heat exchangers

The Gerlinger Tube Bundle Roller (TBR). The TBR achieves this level of efficiency by having the bundle stay on a special load pallet that can rotate the bundle for cleaning at the wash pad, for maintenance purposes, or for aligning the bundle for replacement into the towers.

The Gerlinger TBR adjusts to accept heat exchangers in a variety of shapes and sizes. Once loaded onto the TBR, the hydraulically powered rollers rotate the exchanger body during the cleaning process. After the completion of the cleaning process, the entire package is then picked up and returned for re-installation.

Worksites can improve efficiency and reduce handling incurred with other types of equipment by combining Gerlinger’s Straddle Carrier and TBR to deliver simplified turnaround and save time as well as steps and cost.